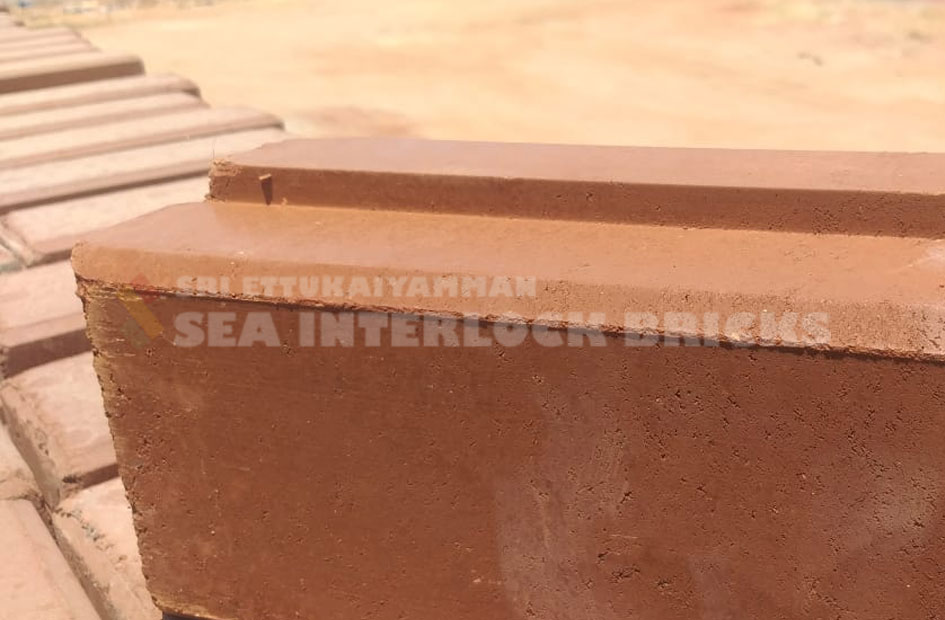

High quality interlocking bricks are made of cement, sand and Stone dust mixed together in appropriate proportions. The required materials are batched and mixed proportionately. Once the required mix is prepared, it is then compressed to form bricks with desirable interlocking patterns. The compression is achieved by using hydraulic compression system. The bricks are then subjected to curing for about 7 days.

During earthquakes, there are various stresses acting on the structure. Conventional bricks are not fully equipped to transfer the seismic loads throughout the structure since the only medium of load transfer is the mortar. If the mortar fails then the whole structure fails under seismic forces. Interlocking bricks are an effective and proven earthquake resistant construction materials. The self locking pattern of the bricks enables the seismic forces to travel across the whole structure equivalently.

High compacted bricks generally result in higher density, which in turn converts itself into high thermal mass. Henceforth, the walls made of high compacted bricks typically furnish warm interiors. Interlocking bricks are less heat intensive. The tests have shown that interlocking bricks provides a much cooler interior (3oC – 5oC). This enables lesser/no use of air conditioners resulting in minimized energy consumption and more cost saving.